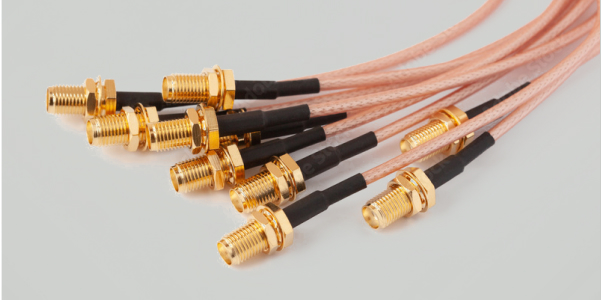

Explore High-Performance RF Cable Assemblies for Superior Signal Integrity!

What are RF Cable Assemblies?

RF cable assemblies are specialized cables used in radio frequency applications to transmit high-frequency signals between components such as antennas, amplifiers, and receivers. They are designed to maintain the signal integrity and minimize losses that occur when a signal is transmitted over a distance.

RF cable assemblies consist of a central conductor, usually made of copper or silver-plated copper, surrounded by a dielectric insulator material. This insulator is then surrounded by a braided shield made of a conductive material such as copper or silver, which provides protection against electromagnetic interference (EMI) and ensures that the signal is transmitted with minimum loss.

There are different types of RF cable assemblies, including coaxial cables, twinaxial cables, and triaxial cables. Coaxial cables are the most common type, consisting of a single central conductor surrounded by a dielectric and a braided shield. Twinaxial cables have two central conductors, while triaxial cables have three.

RF cable assemblies are used in a wide range of applications, including telecommunications, broadcasting, military and aerospace, medical equipment, and scientific research. They are available in different lengths, connector types, and impedance ratings to suit different requirements.

The Advantages of RF Cable Assemblies

Overall, RF cable assemblies are an essential component in high-frequency applications where signal quality and reliability are critical. There are several advantages:

- Low signal loss: RF cable assemblies are designed to minimize signal loss and maintain the integrity of the signal, even over long distances.

- High-frequency capability: RF cable assemblies are capable of transmitting high-frequency signals up to several GHz, making them suitable for a wide range of applications in telecommunications, broadcasting, and other industries.

- EMI shielding: RF cable assemblies are designed with a braided shield that provides excellent protection against electromagnetic interference (EMI) and ensures that the signal is transmitted with minimum loss.

- Durable and reliable: RF cable assemblies are made from high-quality materials and are designed to withstand harsh environmental conditions, making them highly reliable and durable.

- Versatility: RF cable assemblies are available in a range of lengths, connector types, and impedance ratings, making them suitable for a wide range of applications.

- Easy to install: RF cable assemblies are typically plug-and-play, making them easy to install and replace in existing systems.

Applications

RF cable assemblies are widely used in military and defense applications due to their ability to transmit high-frequency signals with low loss and high reliability. Some common military applications include:

- Communication systems: RF cable assemblies are used in a wide range of military communication systems, including radios, satellite systems, and other wireless communication systems.

- Radar systems: RF cable assemblies are used in radar systems to transmit high-frequency signals between radar antennas and other system components. Naval Surface Ships and Submarines commonly use Coaxial HELIAX cables using cable and connectors that are NAVSEA approved for transmitting and receiving digital data within naval vessels.

- Electronic warfare: RF cable assemblies are used in electronic warfare systems to jam or disrupt enemy communication systems.

- Guidance and navigation: RF cable assemblies are used in guidance and navigation systems, including GPS systems and inertial navigation systems.

- Surveillance systems: RF cable assemblies are used in surveillance systems, including drones and unmanned aerial vehicles (UAVs).

- Military vehicles: RF cable assemblies are used in military vehicles for various systems, including communication, navigation, and weapons control systems.

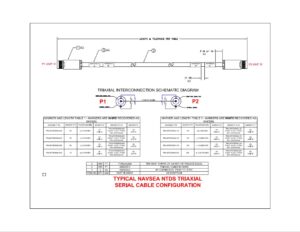

- MIL-STD-1553 Data Bus systems: RF cable assemblies, coaxial and triaxial used for data bus communication on critical assets such as aircraft, vehicles and ships. The protocol, first introduced in 1975, is based upon digital internal time-division multiplexing.

- MIL-STD-1397 Naval Tactical Data System (NTDS): RF cable assemblies, coaxial and triaxial used on AEGIS Weapons Systems (Shipboard or Land Based Radar) as the communication system used in naval vessels for transmitting and receiving digital. (I/O data)

Materials

RF cable assemblies are typically made of high-quality materials that are selected based on the specific requirements of the application. Some common materials used in the construction of RF cable assemblies include:

- RF Connectors, Coaxial, Triaxial: Radio Frequency (RF) Connectors for military applications are designed per Department of Defense Interface Standard MIL-STD-348. RF Connectors per: MIL-DTL-3643, MIL-DTL-3650, MIL-DTL-3655, MIL-DTL-25516, MIL-PRF-31031, MIL-PRF-39012, MIL-PRF-49142, MIL-PRF-55339, MIL-DTL-83517 and NAVSEA 8485339.

- Conductors: The central conductor in RF cable assemblies is typically made of copper or silver-plated copper, which provides good electrical conductivity and corrosion resistance.

- Dielectric materials: The dielectric insulator material is typically made of materials such as polyethylene (PE), polytetrafluoroethylene (PTFE), or fluorinated ethylene propylene (FEP). These materials provide excellent electrical properties and can withstand high temperatures.

- Shielding materials: The shielding material in RF cable assemblies is typically made of a conductive material such as copper or silver, which provides protection against electromagnetic interference (EMI) and ensures that the signal is transmitted with minimum loss.

- Jacket materials: For Military applications the outer jacket of RF cable assemblies is typically made of a Low Smoke Zero Halogen (LSZH) compound, polyethylene (PE), or fluorinated ethylene propylene (FEP). These materials provide protection against abrasion, chemicals, and other environmental factors.